Death in the Mines

By Gulmina Bilal Ahmad | News & Politics | Published 18 years ago

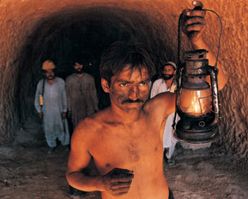

Deep in the bowels of the Balochistan coal mines, thousands of coal miners toil under life-threatening conditions, with little or no safety precautions in place. Bonded for their working life through contractors, young boys of 13 work till they are 30 years old for a paltry sum until their damaged lungs can no longer withstand the chronic exposure to coal dust. Digging thousands of feet below ground, in a hollow tunnel in a mountain, what are the living conditions of the coal miners? What safety standards do they operate under? What is the human cost of mining coal and do the workers get the monetary rewards that they deserve?

Coal is still a significant source of energy and is mined in many countries including Pakistan, which has extensive coal deposits: 184 billion tons in all the four provinces. In the NWFP, Cherat and Hangu have the highest coal deposits, while Balochistan has the richest coal fields in the country.

A coal miner’s life is extremely hazardous and sometimes even fatal. He spends the best years of his life literally in the dark digging for a living under the most adverse conditions.

A typical day for a coal-mine worker in one of the approximately 250 coal mines in Balochistan starts at five a.m. The miner will typically be either from Swat district in the Frontier, or from Afghanistan and between 13 and 30 years. The age scale is very easily defined as typically a miner starts working at 13 and can only work a maximum of 17 years in the mine. According to a survey conducted by Dr. Mukhtiar Zaman, Chief Executive of Abasin Foundation in NWFP and Balochistan, the working life span of a coal miner is 17 years. A prominent coal mine owner from Balochistan, Shiekh Abdul Aziz, denies the charges of child labour in mining and says, “There is no question of employing children of 13 or 14. There is no child labour. We only employ workers from 15 years of age.” The younger ones, with their young unpolluted lungs, are sent to the deepest part of the mine where there is even less ventilation. As the years pass, the miner is no longer able to work that long or that deep and by the age of 30, he is compelled by Pneumoconiosis to stop. According to Dr. Mukhtiar Zaman, Pneumoconiosis, also known as, coal miner’s disease, is a forerunner of tuberculosis.

Pneumoconiosis is a lung disease resulting from chronic exposure to coal dust, its inhalation and deposition. All too often, when the miner is forced by crippling health problems to leave work, he invariably sends his young teenage son to replace him. According to a survey conducted by the Abasin Foundation on 107 respondents, the miners are aware of the health hazards, but with financial compulsions and lack of job opportunities, mining is often the only option available. According to one coal-mine worker, “It is unfair to say that we have a choice whether we should send our sons to mine or not. This is how our life is. Father is replaced by son and son by grandson.”

So what are the financial rewards for risking their lives? The average coal miner works for 15 or 16 hours a day. All of them are daily wage workers brought to the coal mine by a contractor. This contractor works as a middle man: on behalf of the mine owner, he seeks young, able-bodied men or boys from poor families in Swat and Afghanistan. These families are mostly under debt to private money-lenders and so are more than eager to take the lump sum in cash offered by the contractor in exchange for work. The cash payments range from thirty to eighty thousand rupees and the recruit is expected to work the payment off. Since the coal miner’s monthly income is 1800 to 2500 rupees, the workers are mostly indebted for life to the contractors and the mine owners. A source in the Social Security Department of the Balochistan government, who does not wish to be named, calls this arrangement “bonded labour” Even to collect this meagre wage, they have to travel several miles to collect payment. Since the services of the worker have already been bought, he is worked so hard that more often than not, he doesn’t even have time to wash his hands before a meal.

According to another local development worker, Arbab Nizam, “The living conditions of coal miners can be gauged from the fact that a majority of them have an almost permanent thick coating of coal tar on the soles of their feet.”

It is important to mention that in Balochistan hardly any locals are involved in mining since it is considered too much of a health hazard. Most of the workers are from the poverty-stricken Hazara tribe of Afghanistan or from Swat. The only locals are the Pathans of Toba Kakari but they prefer to work in the deepest sections which are more profitable for three months at a time. No Baloch is involved in the mining. There are coal miners who earn as much as 8,000 rupees in the mines, but there is a price to pay for the money. Payment in the mining business is done by the foot. The deeper one digs, the greater the remuneration. This is the kind of excavation that people from Toba Kakari in Balochistan are interested in. Arbab Nizam says, “The bride price nowadays is about three hundred thousand rupees. So young men from Toba Kakari come to the mines, work for a few months in the deepest and most dangerous parts of the mine, earn their bride price money and go home.” Of course, there are health costs as explained by Dr. Mukhtiar Zaman of the Abasin Foundation as there is a greater probability of chest-related diseases as one goes deeper.

It is important to mention that in Balochistan hardly any locals are involved in mining since it is considered too much of a health hazard. Most of the workers are from the poverty-stricken Hazara tribe of Afghanistan or from Swat. The only locals are the Pathans of Toba Kakari but they prefer to work in the deepest sections which are more profitable for three months at a time. No Baloch is involved in the mining. There are coal miners who earn as much as 8,000 rupees in the mines, but there is a price to pay for the money. Payment in the mining business is done by the foot. The deeper one digs, the greater the remuneration. This is the kind of excavation that people from Toba Kakari in Balochistan are interested in. Arbab Nizam says, “The bride price nowadays is about three hundred thousand rupees. So young men from Toba Kakari come to the mines, work for a few months in the deepest and most dangerous parts of the mine, earn their bride price money and go home.” Of course, there are health costs as explained by Dr. Mukhtiar Zaman of the Abasin Foundation as there is a greater probability of chest-related diseases as one goes deeper.

However, Arbab Nizam maintains that “They of course see possible death and disease but then, simultaneously, they also see the Quaid-e-Azam on the rupee note.”

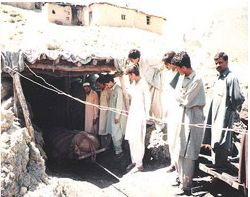

The coal mines employ in the thousands. Just in the 250 mines in Balochistan, there are 40,000 workers. None of these workers are provided any medical coverage. Legally speaking, in case of an accident inside a mine, according to the Mines Law of 1926, the mine owner is supposed to give compensation. However, for accidents outside the mine, the owner does not have any responsibility. According to sources both in NWFP and Balochistan, the usual practice is that in the advent of an accident inside the mine, the worker is carried out so the owner can escape paying any compensation. Anyway the compensation is not much. According to the Mines Law of 1926 the mine owner has to pay around one hundred thousand rupees in compensation. However, there is a difference in the coal-mine workers in Balochistan and the NWFP. According to Dr Mukhtair Zaman, the workers in Balochistan fare slightly better because the mines there are older and more well established. The NWFP mines are smaller, newer and thus the coal miners are bent upon “making hay while the sun shines and make a quick buck.” In Balochistan, according to the Abasin survey, the miner is given slightly better health facilities. This was corroborated by the social security official in Balochistan who declared that in the event of an accident, the worker is usually taken to a private clinic because the contractor has already invested so much money in the initial payment and “does not want to see his money wasted.” The money spent on medical treatment is, of course, put down as a further cash investment for the coal mine worker to pay off.

Most of the accidents in the coal mines happen because of lack of safety precautions. According to an International Labour Organisation (ILO) report, the fatality rate at small mines in poorer countries is up to 90 times higher than in industrialised countries. Underground coal mining is one of the most hazardous operations in the world and occupational accidents occur twice as often among coal miners than among other workers, while fatal accidents occur three times as often. No reliable data about occupational health and safety (OHS) are available in Pakistan because the majority of accidents are not reported to the Labour Department.

Sardar Muhammad Ali Jogezai, another major coal mine owner of Balochistan and head of the Sardar Usman Jogezai Coal Company, maintains that the accident rate in Pakistan and Balochistan, where most of the coal mining is done, is very low as compared to China. Sheikh Abdul Aziz agrees and declares, “Our accident rates are less than China. We have had ten fatal accidents in five years but in China there were forty fatalities in two years.”

According to the official record of the Inspectorate of Mines of the Government of Balochistan, there has been a decrease in the number of fatal accidents and other accidents during the past five years. However, the department officals, who preferred not to be named, claimed that, “Not all these figures might be true as most of the cases are not reported. How can the department track down every fatal accident?” The department official also claimed that media interest has also complicated matters. “The media is hungry for a story. Previously, there was not so much pressure and so if there was an accident it would be reported, compensation paid and that would be the end of it. However, now with newspapers and local channels etc, if the media gets wind of an accident, it makes it into a big story. The coal mine owner is upset and when he is upset it trickles down to the workers.”

According to the official record of the Inspectorate of Mines of the Government of Balochistan, there has been a decrease in the number of fatal accidents and other accidents during the past five years. However, the department officals, who preferred not to be named, claimed that, “Not all these figures might be true as most of the cases are not reported. How can the department track down every fatal accident?” The department official also claimed that media interest has also complicated matters. “The media is hungry for a story. Previously, there was not so much pressure and so if there was an accident it would be reported, compensation paid and that would be the end of it. However, now with newspapers and local channels etc, if the media gets wind of an accident, it makes it into a big story. The coal mine owner is upset and when he is upset it trickles down to the workers.”

Field research has revealed that most of the workers do not even have helmets given to them. Out of a total of 101 coal mine workers interviewed by the Abasin survey, only 25 per cent used protective gear while an overwhelming 75 per cent did not. It is important to point out that protective gear translates into a helmet which 50 per cent wore, while only a small minority wore other protective gear like a mask or gloves. Digging by hand and blasting are the common methods used for mining. The majority of miners are involved in cutting, drilling and transportation of coal and thus the absence of protective gear further increase their health risks.

In spite of modernisation and technological advancement, Pakistan’s coal mines use primitive methods of mining. Field research has revealed that coal mine workers as young as 13 years carry a 25/30 kg sack over a distance of 700 ft on their backs. This finding was corroborated by a number of coal miners but they maintain that there is no other choice as modern equipment is not available. The use of obsolete equipment by modern standards, leads to accidents and low production rates.

The law requires that coal miners be protected. Mines have to be regularly inspected and inspectors are authorised to stop hazardous excavations. In Balochistan there is the Inspectorate of Mines whose task is to inspect and rescue. There is a Central Mines and Rescue Station at Sinjidi near Quetta and four training and rescue stations at Shahrag, Mach, Dukki and Narwar each. These stations have staff that conducts rescue operations and provides training in safety. They swing into action when a mine caves in, burying its workers with it, or when during excavations, poisonous gas causes the death of the workers. However, in order to ensure that such unfortunate incidents are avoided, this Inspectorate at its Central Office at Sinjidi, conducts a course at the end of which a certificate, called the Mine Firdar, is issued to each of the successful course participant. The certified Mine Firdar is qualified to inspect the mines and stop hazardous excavations or halt mining altogether if the inspectors feel that safety precautions have not been taken. Each active mine is supposed to have a Mine Firdar on site. However, the situation on the ground is another matter. The Mine Firdar is definitely on the mine premises, but in the words of one mine worker, ” he is out smoking a cigarette while drawing a salary from the exchequer plus a little on the side from the mine owner to turn a blind eye.” According to developmental consultants like Zia Durrani, if the Mine Firdar enforces the safety standards, a lot of accidents can be avoided.

In their defence, the mine owners declare that installing safety equipments in the mines is expensive and the equipment has to be imported from abroad. Taking this into consideration, the Mines and Mineral Development Department in Balochistan, on the recommendation of the International Labour Organisation, is considering establishing a warehouse in Quetta. The project, which, according to ministry sources, will shortly be launched, consists of the government importing the safety equipment itself and displaying it in the warehouse where it will be available for rent to various coal mine owners. This promises to be a welcome step but the challenge is in the implementation. Most of the ministers of the mining industry in Balochistan are either coal mine owners themselves or at least major financial stakeholders in the mining business, including the present minister, Mr. Masoud Luni. In fact, the Minister was not available for comment and neither was his office willing to offer information when contacted.

It is recommended that the control of hazards should begin at the process, equipment, and plant design levels. When it is not always practical to provide and maintain totally effective engineering controls, appropriate individual respiratory protection equipment should be used for respiratory protection as necessary, suggests Dr. Muktiar Zaman.

In addition to the dangers posed by unsafe mines and hazardous excavation, the general living conditions of the coal miners leave much to be desired. Field research revealed that there is no sanitation facility. Government dispensaries exist but they are usually understaffed and ill-equipped. According to the official figures provided by the Mine Labour Welfare Organisation of the Mine and Mineral Department, there are three high schools, six middle schools , six primary schools, 10 dispensaries and only one hospital run by it. However, even with this modest arrangement, the Department itself maintains that the schools are understaffed and the medical facilities inadequate. The Department declares that it needs “a substantial increase in budget” to fully run these facilities. “The safest bet is to reach the nearest private clinic,” says a coal miner.

According to Mr. Mazhar Mehmood, a former government officer in the Balochistan government, “There was a scheme some years back by the government to construct proper accommodation for the miners of the coal mines. However, these houses were constructed only on paper. In real terms, they were constructed in the cities and then sold off by the government officials of the concerned department at a profit.” Sheikh Abdul Aziz and Sardar Ali Ahmed Jogezai maintain that coal mine owners are aware of the miners’ housing needs and that they provide the workers construction material .The workers construct the houses themselves. However, for smaller mine owners such an investment is not possible.

Unless the government realises the urgency and the need to improve these facilities, the life of the coal miners will remain at risk, while mine owners continue to reap the benefits.